At Very High Speed

Inconel 718, Inconel 625, Nimonic 90, Haynes 282, etc

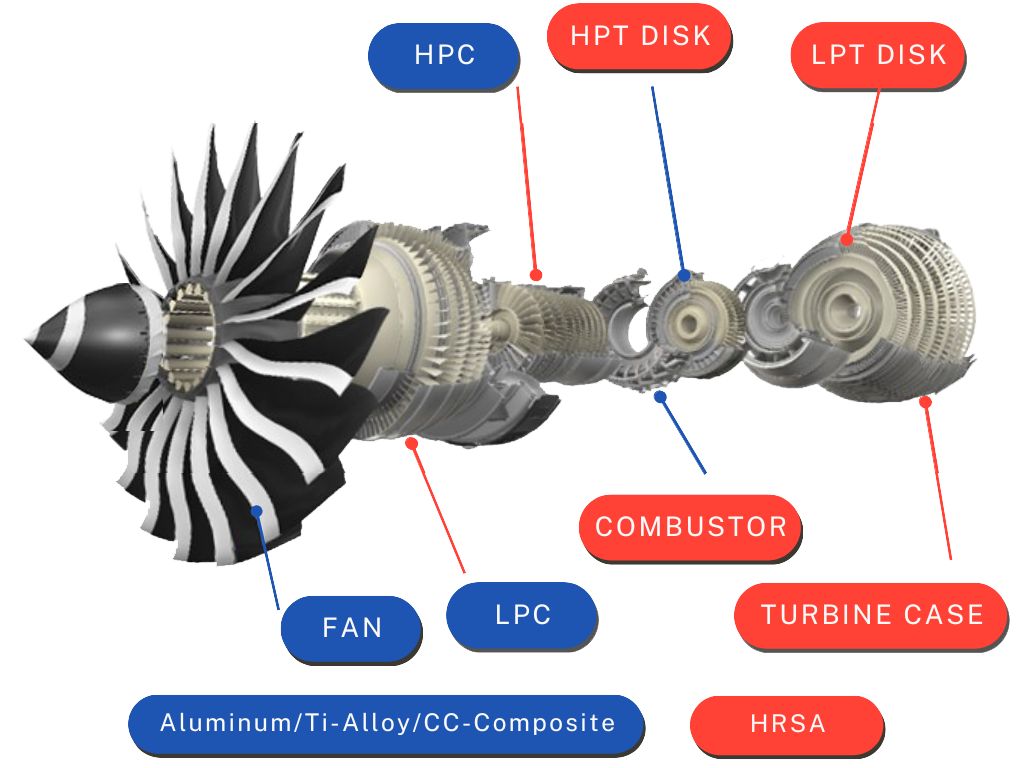

Aero Engine Parts

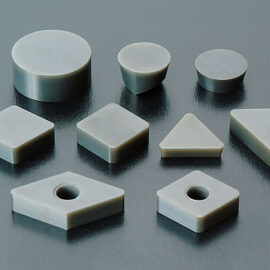

An aero engine primarily consists of 8 parts enclosed in the engine cover. They consist of a fan, a low-pressure compressor, a high-pressure compressor, a combustion chamber, a high-pressure turbine disc, a low-pressure turbine disc, turbine blades and a turbine case. Some engines use a blisk instead of assembled disc and blades. A blisk is an integrated form of turbine blades and turbine disc. The pre-combustion parts are usually made of Titanium alloys, Aluminium Alloys or composites. The combustion chamber and post combustion parts are made with heat resistant super alloys which are nickel or cobalt based alloys. They are also referred as exotic alloys or super alloys in various regions. Klang Aero specializes in providing solutions for machining (turning, milling and grooving) of heat resistant super alloys like Inconel, Haynes, Nimonic, Rene, etc. with high technology ceramic cutting tools.

Industries

Aerospace

Oil & Gas

Power Generation

Higher Cutting Speeds

Higher Life

Lower Cost Per Component

Our Products

About Klang

Based in Germany, we have specialized in the development, manufacturing and sale of precision tools equipped with ceramic cutting materials which are ultra-hard and ultra-tough for use in the aerospace industry. As a leading manufacturer of tools with lasered cutting edges, we offer machining solutions in the areas of turning, milling and grooving of heat resistant superalloys commonly used in the aerospace industry, the oil and gas industry and the power generation industry. In order to be able process these precision tools economically, we recognized early on that we had to develop further from the old production technology of grinding to new technologies such as the laser ablation process.