First recommendation for machining through scale

Excellent notch wear resistance ideal for machining scale

Features

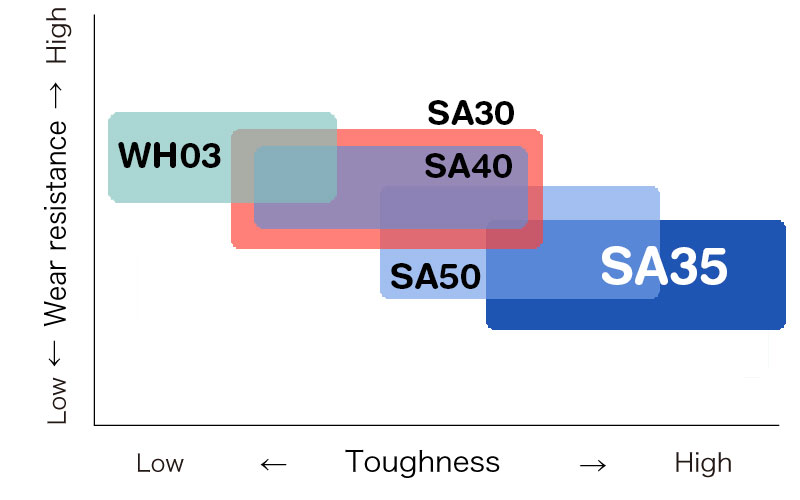

- Ceramic with the highest fracture resistance

- Best for machining where scale or interruptions exist

- Best grade for roughing Waspaloy with scale

Tooling application

Finishing Heat resistant alloys

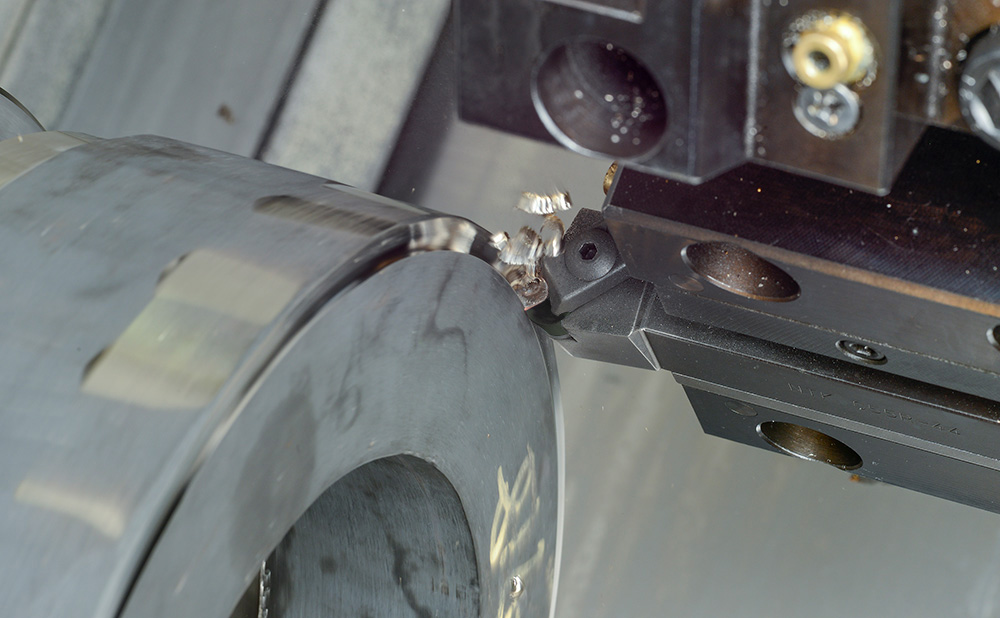

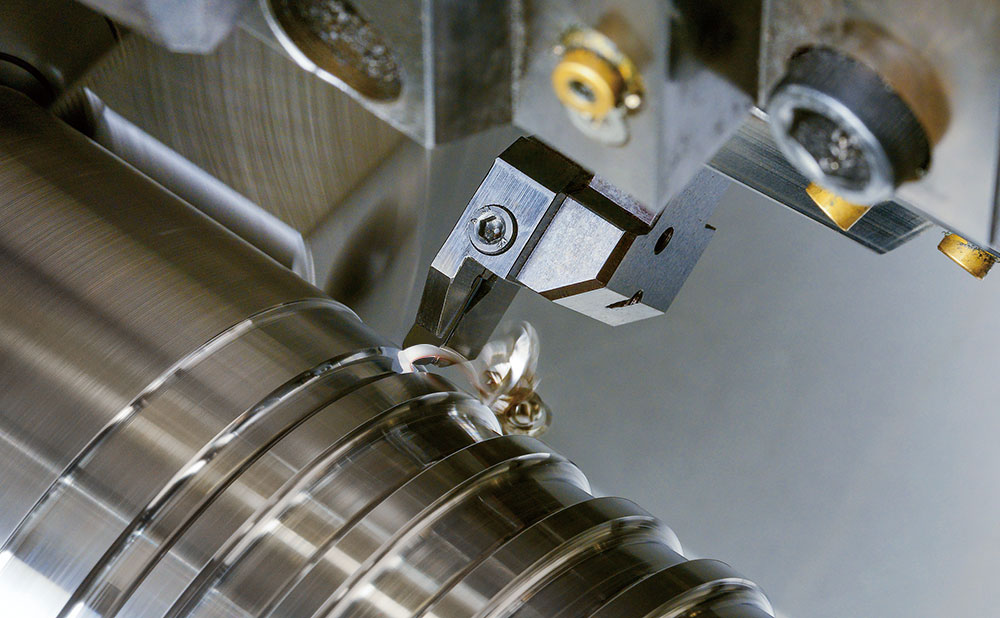

Turning / grooving through scale

| Cutting conditions

| Grade | Material | Operation type | Machining | Cutting speed (m/min) | Feed(mm/rev) | DOC(mm) | Coolant |

|---|---|---|---|---|---|---|---|

| SA35 | Heat resistant alloys | Turning | Roughing with scale | 180 – 240 | 0.2 – 0.35 | 1.0 – 5.0 | WET |

| Grooving | 0.07 – 0.17 | – |

Why are Sialon ceramics so effective at high-speed machining of heat resistant alloys?

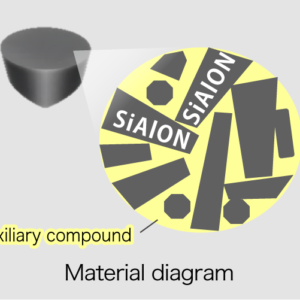

Silicon nitride (Si3N4) is combined with Aluminum (Al) and oxygen (O) to make SiAlON.

Sialon has needle-shaped particles similar to that of Silicon nitride.

The arrangement of these particles makes the material withstand the impact force during cutting.

The addition of the alumina improves its heat resistance characteristics.

The property advantages makes it perfect for machining heat resistant alloys.

| Machining Inconel with scale

| Milling Inconel

| Case Study

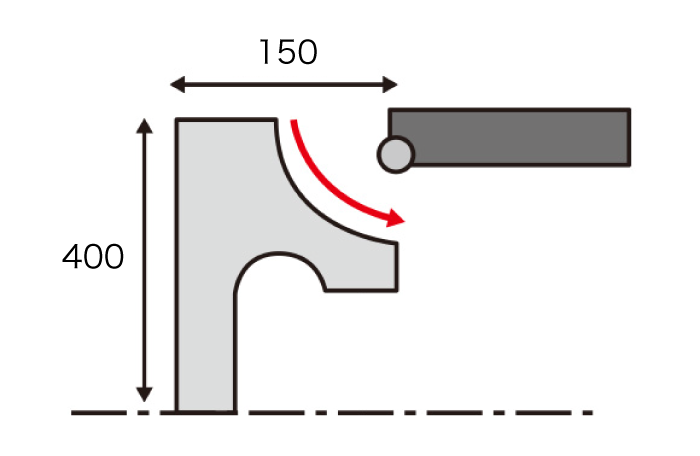

| Ring (Roughing with scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SA35 |

1 pass |

| Current tool (competitor’s whisker) |

1 pass |

High feed rate is possible because of SA35’s toughness. It achieved 2.5 times more efficient results compared to the competitor’s whisker.

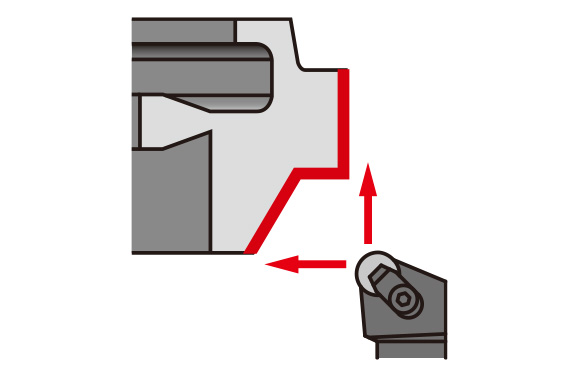

| Aircraft part (Roughing with scale) | |

|---|---|

|

|

|

|

|

|

|

|

|

|

| SA35 |

1 pass |

| Current tool (competitor’s Sialon ceramic) |

1 pass Chipping |

SA35 insert had more stable performance and no edge chipping compared to the competitor’s Sialon grade.